| Items |

HCLT 62

READY HCLT62 0.625" DIA. Length MIN=1.000" MAX=6.000" Custom Compact Bender

List Price Quote

|

HCLT 100

READY HCLT100 1.000" DIA. Length MIN=1.500" MAX=8.000" Custom Compact Bender

List Price Quote

|

HCLT 150

READY HCLT150 1.500" DIA. Length MIN=2.000" MAX=8.000" Custom Compact Bender

List Price Quote

|

HCLT 200

READY HCLT200 2.00" DIA. Length MIN=3.000" MAX=8.000" Custom Compact Bender

List Price Quote

|

|

Description

|

N/A

- Designed to fit "tight" die spaces, smallest bender footprint

- Manufactured to produce over to 500,000 parts per year

- Custom bend options available: See Classified Bend chart for details

- A variety of Rocker diameters, and Saddle length/heights available

- Metric mounting holes and other custom options like V-Dart stiffeners, pad and tooth benders available

- Hemmer option available: Designed to form a completely flat bend in just two operations

- Hardened (Rc 48-52) A2 Tool Steel Saddle with Fully Hardened (Rc 56-62) S7 Tool Steel Rocker

- Note: Custom Benders Require a "Request A Quote" form to be submitted for pricing and delivery

- 3D CAD models available at time of order

|

|

Features

|

N/A

- Designed to fit tight die spaces, small footprint.

- Recommended for high production applications.

- Hardened tool steel, all surfaces precision ground. Rockers Rc 56-62. Saddles Rc 48-52. Chase or Yoke mounting by die maker.

- Standards in stock for fast delivery. Special compact benders can be made to your height and length requirements upon request.

|

|

Saddle Width (SW)

|

N/A

1.000 in

|

N/A

1.500 in

|

N/A

2.000 in

|

N/A

3.000 in

|

|

Rocker Angle

|

N/A

87 º

|

|

Rocker Dimension (B)

|

N/A

0.212 in

|

N/A

0.339 in

|

N/A

0.508 in

|

N/A

0.678 in

|

|

Rocker Dimension (C)

|

N/A

0.195 in

|

N/A

0.312 in

|

N/A

0.468 in

|

N/A

0.624 in

|

|

Rocker Dimension (J)

|

N/A

0.246 in

|

N/A

0.393 in

|

N/A

0.590 in

|

N/A

0.786 in

|

|

Note

|

N/A

The original compact benders called CBT and CLT are not discontinued.

Ends of saddles are not ground.

|

|

Socket Head Cap Screw Dimensions

|

N/A

1/4 in.-20

|

N/A

5/16 in.-18

|

N/A

5/16 in.-18

|

N/A

1/2 in.-13

|

|

Length (X)

|

N/A

1.500 to 3.000 in

|

N/A

2.000 to 4.000 in

|

N/A

2.750 to 5.500 in

|

N/A

4.000 to 5.500 in

|

|

Height (H)

|

N/A

2.000 to 3.000 in

|

N/A

2.000 to 3.000 in

|

N/A

2.750 to 3.750 in

|

N/A

3.000 to 4.000 in

|

|

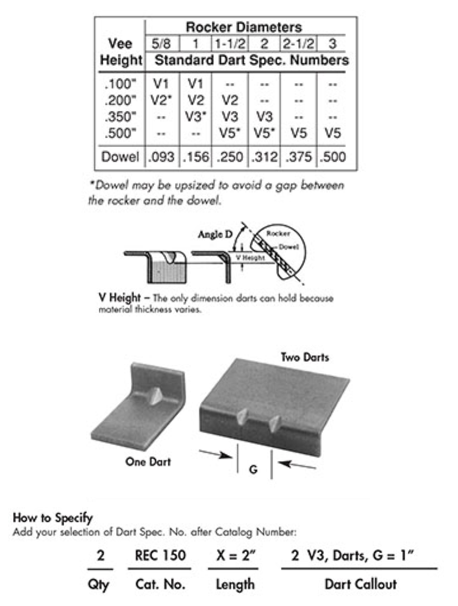

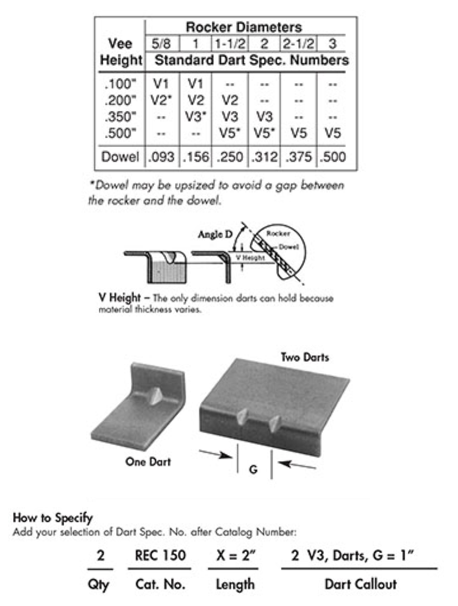

Dart Stiffener Overview

|

N/A

Standard darts are shown in the table below or you can specify your own angle and dowel size

Darts are rolled into the part during bending, reducing springback and stiffening the part. Darts are produced using dowels through the rocker and require relief grooves in the anvil. The side angles of the darts are a function of the angle and size of the dowel.

Darts are available as spcifiable extras on all READY Benders®. Darts are central on a 45° angle unless detailed.

Eliminate:

- Galling and Maintenance

- Unattractive Parts

- Secondary Operations

|

|

Product Code

|

N/A

RB

|