Manufacturer Part# / Cross Reference Search

Please use this search function to find READY die set components that are equivalent to commonly used pins, bushing, ISO Springs, and Gas Springs from other manufacturers.  Please Note: We believe this cross reference to be accurate. Please review the specifications to ensure the item will work in your application. Gas Spring equivalents were based on body dimensions, on contact force and stroke length.

Please Note: We believe this cross reference to be accurate. Please review the specifications to ensure the item will work in your application. Gas Spring equivalents were based on body dimensions, on contact force and stroke length.

READY Medium Production (RBM) Custom Metric Benders

READY Medium Production (HIB, RBM) Benders

- Designed to produce up to 300,000 parts per year

- Custom bend options available: See Classified Bend chart for details

- Custom lengths available: MIN=Gib length, MAX up to 609.6mm or 914.4mm on larger diameter models

- Mounting holes and other custom options like v-dart stiffeners, pad and tooth benders are available

- S7 Tool Steel Full Hardened (RC 56 to 62) Rocker for long life

- Machinable Saddle with coated socket for lubrication and durability

- Note: Custom Benders Require a "Request A Quote" form to be submitted for pricing

- 3D CAD models available at time of order

Unit of Measure

| Items |

/Asset/a1089.jpg /Asset/a1089.jpg RBM 62 READY MePro RBM62 15.88mm DIA. Length MIN=28.6mm MAX=609.6mm Custom Metric Bender List Price $475.00

|

/Asset/a1089.jpg /Asset/a1089.jpg RBM 100 READY MePro RBM100 25.4mm DIA. Length MIN=38.1mm MAX=609.6mm Custom Metric Bender List Price $565.00

|

/Asset/a1089.jpg /Asset/a1089.jpg RBM 150 READY MePro RBM150 38.1mm DIA. Length MIN=50.8mm MAX=914.4mm Custom Metric Bender List Price $725.00

|

/Asset/a1089.jpg /Asset/a1089.jpg RBM 200 READY MePro RBM200 50.8mm DIA. Length MIN=63.5mm MAX=914.4mm Custom Metric Bender List Price $1,020.00

|

/Asset/a1089.jpg /Asset/a1089.jpg RBM 250 READY MePro RBM250 63.5mm DIA. Length MIN=76.2mm MAX=914.4mm Custom Metric Bender List Price $1,455.00

|

|||||

| Description |

N/A

|

N/A

|

N/A

|

N/A

|

N/A

|

|||||

| Features |

N/A

|

|||||||||

|

Rocker Diameter |

N/A 15.88 mm | N/A 25.4 mm | N/A 38.1 mm | N/A 50.8 mm | N/A 50.8 mm | |||||

| Part Thickness (PT) | N/A 0.25 to 1 mm | N/A 1 to 1.9 mm | N/A 1.9 to 3 mm | N/A 3 to 4.1 mm | N/A 4.1 to 5.3 mm | |||||

| Part Height Check (PH)1 | N/A 6.35 mm | N/A 9.9 mm | N/A 14.8 mm | N/A 14.8 mm | N/A 24.6 mm | |||||

| In Stock Length (X) | N/A 304.8 mm609.6 mm | N/A 304.8 mm609.6 mm | N/A 304.8 mm609.6 mm914.4 mm | N/A 304.8 mm609.6 mm914.4 mm | N/A 304.8 mm609.6 mm914.4 mm | |||||

| Minimum Length | N/A 28.6 mm | N/A 38.1 mm | N/A 50.8 mm | N/A 63.5 mm | N/A 76.2 mm | |||||

| Maximum Length (X) | N/A 609.6 mm | N/A 609.6 mm | N/A 914.4 mm | N/A 914.4 mm | N/A 914.4 mm | |||||

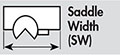

| Saddle Width (SW) |

N/A

53.98 mm

|

N/A

73.03 mm

|

N/A

98.42 mm

|

N/A

123.83 mm

|

N/A

149.23 mm

|

|||||

| Saddle to Front (SF) Width |

N/A

19.05 mm

|

N/A

28.58 mm

|

N/A

38.10 mm

|

N/A

47.63 mm

|

N/A

57.15 mm

|

|||||

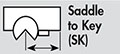

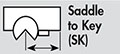

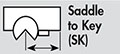

| Saddle to Key (SK) Width |

N/A

34.93 mm

|

N/A

44.45 mm

|

N/A

60.33 mm

|

N/A

76.20 mm

|

N/A

92.08 mm

|

|||||

| Saddle Height (SH) |

N/A

22.23 mm

|

N/A

34.93 mm

|

N/A

47.63 mm

|

N/A

60.33 mm

|

N/A

73.03 mm

|

|||||

| Rocker Angle | N/A 28.6 º | N/A 38.1 º | N/A 50.8 º | N/A 63.5 º | N/A 76.2 º | |||||

| Rocker Dimension (B) |

N/A

87 mm

|

|||||||||

| Rocker Dimension (C) | N/A 5.39 mm | N/A 8.61 mm | N/A 12.90 mm | N/A 17.22 mm | N/A 21.54 mm | |||||

| Rocker Dimension (J) | N/A 4.95 mm | N/A 7.93 mm | N/A 11.89 mm | N/A 15.85 mm | N/A 19.81 mm | |||||

| Popular Bender Options | N/A 6.24 | N/A 9.98 | N/A 14.97 | N/A 19.96 | N/A 24.95 | |||||

| The "Hemmer" | N/A | |||||||||

| Pad Benders | N/A | |||||||||

| Bending without Tool Marks | N/A 1 | |||||||||

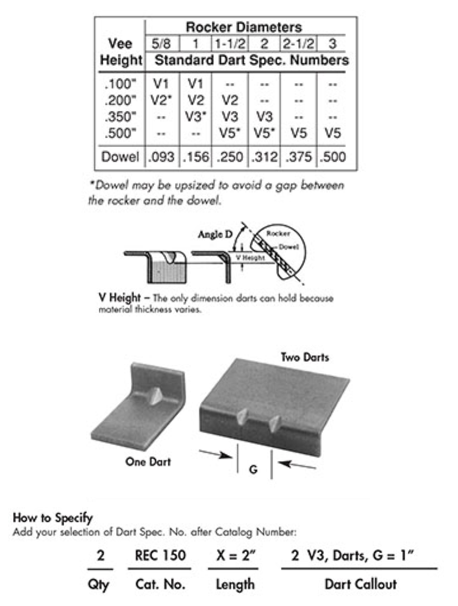

| Dart Stiffener Overview |

N/A

Standard darts are shown in the table below or you can specify your own angle and dowel size Darts are rolled into the part during bending, reducing springback and stiffening the part. Darts are produced using dowels through the rocker and require relief grooves in the anvil. The side angles of the darts are a function of the angle and size of the dowel. Darts are available as spcifiable extras on all READY Benders®. Darts are central on a 45° angle unless detailed. Eliminate:

|

|||||||||

| Product Code | N/A RB | |||||||||

|

||||||||||