Manufacturer Part# / Cross Reference Search

Please use this search function to find READY die set components that are equivalent to commonly used pins, bushing, ISO Springs, and Gas Springs from other manufacturers.  Please Note: We believe this cross reference to be accurate. Please review the specifications to ensure the item will work in your application. Gas Spring equivalents were based on body dimensions, on contact force and stroke length.

Please Note: We believe this cross reference to be accurate. Please review the specifications to ensure the item will work in your application. Gas Spring equivalents were based on body dimensions, on contact force and stroke length.

- Designed to produce up to one million parts, ideal for most stamping dies.

- In stock lengths: 12", 24" and up to 36" long.

- Segment stock lengths to reduce your tooling budget; quick delivery.

- Benders are now less expensive than wipe tooling.

Unit of Measure

Features

Features |

N/A

|

Specifications

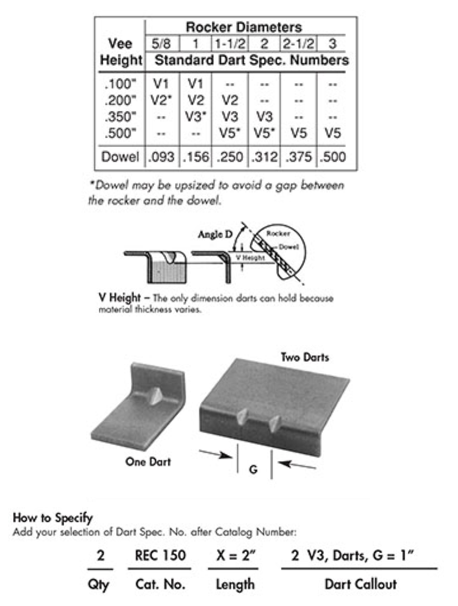

Dart Stiffeners

Dart Stiffener Overview |

N/A

Standard darts are shown in the table below or you can specify your own angle and dowel size Darts are rolled into the part during bending, reducing springback and stiffening the part. Darts are produced using dowels through the rocker and require relief grooves in the anvil. The side angles of the darts are a function of the angle and size of the dowel. Darts are available as spcifiable extras on all READY Benders®. Darts are central on a 45° angle unless detailed. Eliminate:

|

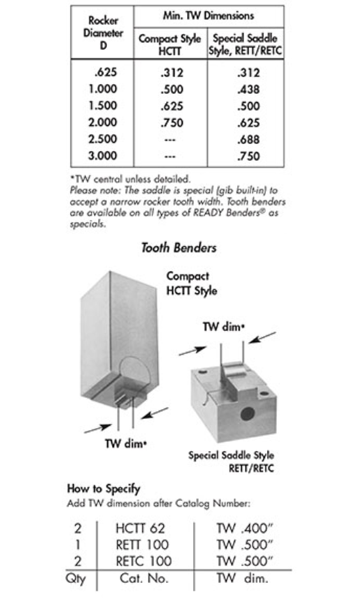

Tooth Benders

Tooth Bender Overview |

N/A

Tooth benders use special rockers to eliminate die/part interferences. Often the saddle needs to be made special without gibs in one peice. Send prints for a quotation.

|

Over Square Bends

Over Square Bend Overview |

N/A

The READY Bender's ® ability to bend 45° beyond ninety (135° PA) is one of its greatest features. Customers buy standard benders and do this simple alteration themselves, adding a degree or two of overbend to the rocker. This easy alteration is done by grinding the bending jaw of the rocker, while not distrubing the working radius of the bending lobe (grind past centerline). For assistance, call READY Technology and we will give you the necessary dimensions to make this alteration

|

Pad Benders

Pad Benders Overview |

N/A

Pads can help in many bender applications. By activating the bender on top of a pad, you isolate the rocker from the part on the critical holddown surface. NO CONTACT = NO MARK Important Pad Functions

When Using Pads, READY Technology Reommends:

|

- 1 To use standard benders, PH should exceed these dimensions. Fax prints for specials.