Manufacturer Part# / Cross Reference Search

Please use this search function to find READY die set components that are equivalent to commonly used pins, bushing, ISO Springs, and Gas Springs from other manufacturers.  Please Note: We believe this cross reference to be accurate. Please review the specifications to ensure the item will work in your application. Gas Spring equivalents were based on body dimensions, on contact force and stroke length.

Please Note: We believe this cross reference to be accurate. Please review the specifications to ensure the item will work in your application. Gas Spring equivalents were based on body dimensions, on contact force and stroke length.

- Ideal for retro-fits to improve productivity and decrease costly maintenance.

- Proven quality and dependability in dies for years.

- Readily available.

- Oversize press fit end for die shoe and nominal size end for bushing.

- Interchangeable with familiar brands.

Unit of Measure

Pricing

|

Specifications

|

Dimensions

|

Advantages

|

Plain and Ball Bearing Components

|

Additional Information

Specifications

Brands |

N/A Ready |

Nominal Inside Diameter A (Decimal) |

N/A 0.750 in |

Nominal Inside Diameter A (Fractional) |

N/A 3/4 in |

Material |

N/A Bronze |

Equivalent Part Numbers |

N/A Danly: 6-06-24 |

Product Code |

N/A SB |

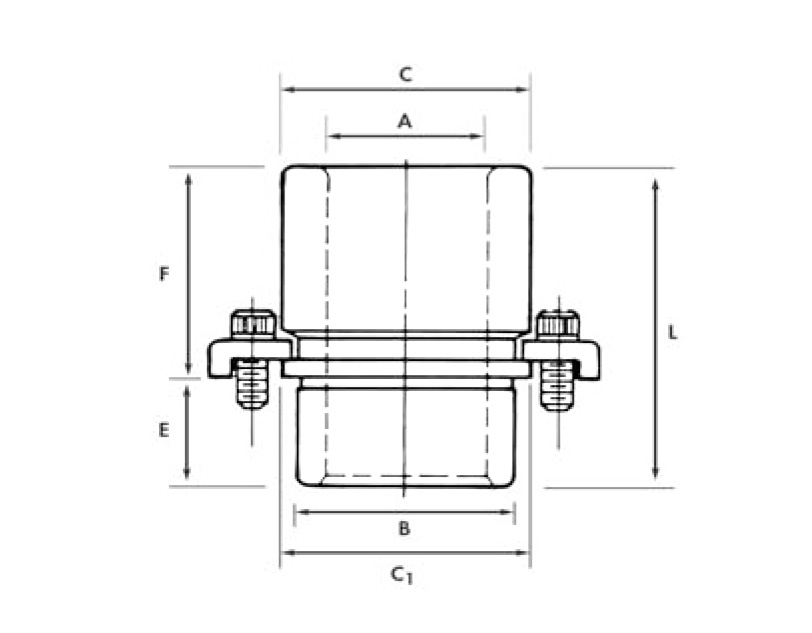

Dimensions

Dimension B |

N/A 1-1/8 in |

Dimension C |

N/A 1.17 in |

Dimension E |

N/A 11/16 in |

Dimension F |

N/A 1-3/4 in |

Dimension C1 |

N/A 1.26 in |

Dimension L |

N/A 2-7/16 in |

Diagram |

N/A

Ready Demountable Bushing |

Advantages

Advantages |

N/A

Our patented Sintered Bronze Bushings offer many advantages over plated bronze bushings.

The second problem with plating is that the thickness of the bronze layer depends on the plating time. A thick bronze layer is simply too costly to produce, and on large diameter bushings in particular, problems arise when the thin plating wears away and the underlying steel comes in contact with the guide pin. Ready's Sintered Bronze Bushings solve both problems. Using a patented manufacturing process, a layer of bronze is sintered to the inside diameter of the steel bushing, creating a strong, reliable mechanical bond. The thickness of the bronze layer is not limited by time or cost constraints, so it is thicker than plated bronze, and it increases proportionally with the bushing diameter. You can test the bond strengths yourself. Cut through the diameter of a plated bushing and you stand a good chance to see peeling. Do the same with our sintered bushing and you will see that the bronze-steel bond is unaffected. If you need to shorten the inserted diameter to fit our bushing into a thin stripper plate, you can do so without harming it. There is a third advantage to our sintered bushings. Because sintered bronze is porous, it holds the lubrication oil in place and helps to maintain an unbroken lubrication layer, which improves wear resistance. The bronze pores act as small oil reservoirs, so our Sintered Bronze Bushings are more forgiving if maintenance has been overlooked. However, for best results, we recommend regular, periodic lubrication with a high viscosity oil. |

Plain and Ball Bearing Components

Plain and Ball Bearing Components |

N/A

You will see a number of innovative ideas designed to increase the performance of your stamping tools, reduce your inventory costs, simplify die assembly and maintenance, and maximize available die space. Here are some of the highlights:

|

Additional Information

Additional Information |

N/A

We offer the full range, inch & metric.

|