Manufacturer Part# / Cross Reference Search

Please use this search function to find READY die set components that are equivalent to commonly used pins, bushing, ISO Springs, and Gas Springs from other manufacturers.  Please Note: We believe this cross reference to be accurate. Please review the specifications to ensure the item will work in your application. Gas Spring equivalents were based on body dimensions, on contact force and stroke length.

Please Note: We believe this cross reference to be accurate. Please review the specifications to ensure the item will work in your application. Gas Spring equivalents were based on body dimensions, on contact force and stroke length.

- Low cost, versatile design

- Fits in smallest die space

- Fast delivery even for options

- Interchangeable tolerances, metric

- Hardened components, high production

- All units come equipped with a mechanical die spring return a Ready SuperString®

Unit of Measure

Specifications

|

Note

|

Dimensions

|

How to Select Right Unit

|

CAMDRIVE® Do's and Don'ts

|

The CAMDRIVE® Rappel

|

Positive Return Option

|

Self-Lubricating Bronze Bushing Standard

|

Shaped Punch Option

|

Angle Mount Option

|

Retainer Mount Option

|

Standard Punch Option

|

Accessories

Specifications

Brands |

N/A CAMDRIVE® Ready |

Metric Tonne |

N/A 5 ton |

United States (US) Ton |

N/A 5.5 ton |

Maximum Strip Force |

N/A 320 daN719 lb |

Point (D) |

N/A 9.5 to 14.2 mm0.374 to 0.559 in |

Maximum Stroke (A) |

N/A 28 mm1.102 in |

Product Code |

N/A CD |

Note

Note |

N/A

Maximum Trigger Stroke = A Minimum Trigger Stroke = 75% of A Maximum Work Stroke = 90% of A All dimension in mm and inch, except when otherwise stated All dimension are nominal unless tolerance is stated |

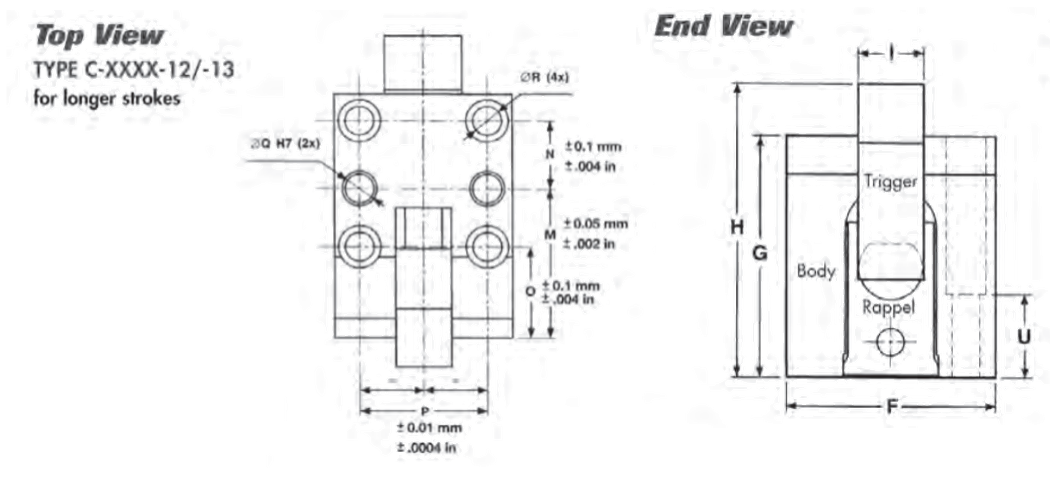

Dimensions

Dimension (B) |

N/A 42 mm1.654 in |

Dimension (C) |

N/A 16 mm0.630 in |

Dimension (F) |

N/A 78 mm3.071 in |

Dimension (S) |

N/A 119 mm4.685 in |

Dimension (G) |

N/A 87 mm3.425 in |

Dimension (H) |

N/A 106 mm4.173 in |

Dimension (O) |

N/A 42 mm1.654 in |

Dimension (I) |

N/A 24 mm0.945 in |

Dimension (J) |

N/A 9 mm0.354 in |

Dimension (K) |

N/A 22 mm0.866 in |

Dimension (L) |

N/A 28 mm1.102 in |

Dimension (M) |

N/A 66 mm2.598 in |

Dimension (N) |

N/A 35 mm1.377 in |

Dimension (P) |

N/A 56 mm2.205 in |

Dimension (Q) |

N/A 10 mm |

Dimension (R) |

N/A M10 mm |

Dimension (T) |

N/A 6 mm0.236 in |

Dimension (U) |

N/A 25 mm0.984 in |

Dimension (V) |

N/A 9 mm0.354 in |

Dimension (W) |

N/A 30 mm1.181 in |

Diagram (End / Top View) |

N/A

Camdrive Top and End View -12 and -13 Models |

Diagram (Side View) |

N/A

Camdrive Side View All Models |

How to Select Right Unit

How to Select Right Unit |

N/A

|

CAMDRIVE® Do's and Don'ts

CAMDRIVE® Do's and Dont's |

N/A

DO: key in back of unit to resist force. DO: effect piercing in last quarter of max stroke A. DO: remember punch stroke equals press stroke (1:1 ratio). DON'T: mount CAMDRIVE® greater than ±15° without using angle mount option trigger. Note: ±30° max angle with option. No positive return on angle mounts. DON'T: overstroke the unit. Max trigger stroke = 90% of A |

The CAMDRIVE® Rappel

The CAMDRIVE® Rappel |

N/A The rapple is an internal component that differs with each available option. A rappel can always be changed to a different configuration later providing maximum user flexibility. |

Positive Return Option

Positive Return Option |

N/A

|

Self-Lubricating Bronze Bushing Standard

Self-Lubricating Bronze Bushing Standard |

N/A

|

Shaped Punch Option

Shaped Punch Option |

N/A

|

Angle Mount Option

Angle Mount Option |

N/A

|

Retainer Mount Option

Retainer Mount Option |

N/A

|

Standard Punch Option

Standard Punch Option |

N/A

|