Manufacturer Part# / Cross Reference Search

Please use this search function to find READY die set components that are equivalent to commonly used pins, bushing, ISO Springs, and Gas Springs from other manufacturers.  Please Note: We believe this cross reference to be accurate. Please review the specifications to ensure the item will work in your application. Gas Spring equivalents were based on body dimensions, on contact force and stroke length.

Please Note: We believe this cross reference to be accurate. Please review the specifications to ensure the item will work in your application. Gas Spring equivalents were based on body dimensions, on contact force and stroke length.

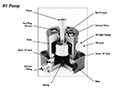

HYDROCAM® H-1 Hydraulic Pumps with H2 Piercing/Forming Unit

HYDROCAM®

Ready recommends using only a premium grade of hydraulic oil.

The H-1 pump is available in six standard sizes. Each pump has four ports to activate up to four identical H-2 units. The quantity, size, and stroke length of the H-2 units hosed to each pump determines the size and oil volume of the pump needed. Pumps can be up to six feet away from H-2 units. This allows you to free up critical die space and balance die loads.

The H-1 pump is available in six standard sizes. Each pump has four ports to activate up to four identical H-2 units. The quantity, size, and stroke length of the H-2 units hosed to each pump determines the size and oil volume of the pump needed. Pumps can be up to six feet away from H-2 units. This allows you to free up critical die space and balance die loads.

Unit of Measure

| Items |

/Asset/a1070.jpg /Asset/a1070.jpg H1-5 HYDROCAM® 3.051 Cubic Inch (in³) Total Volume (VT) H-1 Hydraulic Pump List Price Quote

|

/Asset/a1070.jpg /Asset/a1070.jpg H1-8 HYDROCAM® 4.882 Cubic Inch (in³) Total Volume (VT) H-1 Hydraulic Pump List Price Quote

|

/Asset/a1070.jpg /Asset/a1070.jpg H1-13 HYDROCAM® 7.933 Cubic Inch (in³) Total Volume (VT) H-1 Hydraulic Pump List Price Quote

|

/Asset/a1070.jpg /Asset/a1070.jpg H1-20 HYDROCAM® 12.205 Cubic Inch (in³) Total Volume (VT) H-1 Hydraulic Pump List Price Quote

|

/Asset/a1070.jpg /Asset/a1070.jpg H1-40 HYDROCAM® 24.409 Cubic Inch (in³) Total Volume (VT) H-1 Hydraulic Pump List Price Quote

|

|||||

| Description |

N/A

Ready recommends using only a premium grade of hydraulic oil. The H-1 pump is available in six standard sizes. Each pump has four ports to activate up to four identical H-2 units. The quantity, size, and stroke length of the H-2 units hosed to each pump determines the size and oil volume of the pump needed. Pumps can be up to six feet away from H-2 units. This allows you to free up critical die space and balance die loads. |

|||||||||

| Brands | N/A HYDROCAM® Ready | |||||||||

| Note | N/A | |||||||||

| Metric Force | N/A | |||||||||

| Dimension (L1) at 25 Millimeter (mm) Stroke | N/A | |||||||||

| Dimension (L1) at 50 Millimeter (mm) Stroke | N/A | |||||||||

| Dimension (L1) at 75 Millimeter (mm) Stroke | N/A | |||||||||

| Dimension (L1) at 100 Millimeter (mm) Stroke | N/A | |||||||||

| Dimension (L2) | N/A | |||||||||

| Dimension (L3) | N/A | |||||||||

| Dimension (L4) | N/A | |||||||||

| Dimension (L5) at 25 Millimeter (mm) Stroke | N/A | |||||||||

| Dimension (L5) at 50 Millimeter (mm) Stroke | N/A | |||||||||

| Dimension (L5) at 75 Millimeter (mm) Stroke | N/A | |||||||||

| Dimension (L5) at 100 Millimeter (mm) Stroke | N/A | |||||||||

| Dimension (L6) | N/A | |||||||||

| Dimension (L7) | N/A | |||||||||

| Dimension (L8) | N/A | |||||||||

| Dimension (L9) | N/A | |||||||||

| Dimension (B1) | N/A | |||||||||

| Dimension (B2) | N/A | |||||||||

| Dimension (B3) | N/A | |||||||||

| Dimension (Ht 1) | N/A | |||||||||

| Dimension (Ht 2) | N/A | |||||||||

| Dimension (Ht 3) | N/A | |||||||||

| Diameter (D1) | N/A | |||||||||

| Diameter (D2) (x2) | N/A | |||||||||

| Diameter (D3) (x2) | N/A | |||||||||

| Diameter (D4) | N/A | |||||||||

| Diameter (D5) | N/A | |||||||||

| Diameter (D6) (x4) Metric Thread Size | N/A | |||||||||

| Piston Diameter (D7) | N/A | |||||||||

| Nominal Head Punch Shank Diameter (D8) | N/A | |||||||||

| Dimension (D9) Thread Size of Bolt | N/A | |||||||||

| Diameter (G) British Standard Pipe Parallel Thread (BSPP) | N/A | |||||||||

| De-Rated Force | N/A | |||||||||

| VC Volume/Stroke (mm) | N/A | |||||||||

| Maximum Force at 400 bar (5802 psi) Pressure | N/A | |||||||||

| Volume at 25 Millimeter (mm) Stroke | N/A | |||||||||

| Volume at 50 Millimeter (mm) Stroke | N/A | |||||||||

| Volume at 75 Millimeter (mm) Stroke | N/A | |||||||||

| Volume at 100 Millimeter (mm) Stroke | N/A | |||||||||

| Standard Minimum Return Force at 100 bar (1,450 psi) | N/A | |||||||||

| Maximum Return Force at 150 bar (2,175 psi) Pressure | N/A | |||||||||

| Total Volume (VT) | N/A 50 cm³3.051 in³ | N/A 80 cm³4.882 in³ | N/A 130 cm³7.933 in³ | N/A 200 cm³12.205 in³ | N/A 400 cm³24.409 in³ | |||||

| Total Volume (Volume/Stroke Per mm) | N/A 2.235 cm³3.4636 in³ | N/A 3.318 cm³5.1434 in³ | N/A 3.318 cm³5.1434 in³ | N/A 7.854 cm³12.1737 in³ | N/A 13.273 cm³20.5735 in³ | |||||

| Die Open Height (Ht 1) | N/A 133 mm5.236 in | N/A 145 mm5.709 in | N/A 195 mm7.677 in | N/A 166 mm6.535 in | N/A 195 mm7.677 in | |||||

| Height of Base (Ht 2) | N/A 41 mm1.614 in | N/A 42 mm1.654 in | N/A 57 mm2.244 in | N/A 46 mm1.811 in | N/A 50 mm1.969 in | |||||

| Maximum Volume Stroke (Ht 4) | N/A 23 mm0.906 in | N/A 24 mm0.945 in | N/A 39 mm1.535 in | N/A 26 mm1.024 in | N/A 30 mm1.181 in | |||||

| Approach Stroke (Ht 5) | N/A 8 mm0.315 in | |||||||||

| Piston Diameter (D1) | N/A 53.34 mm2.100 in | N/A 65 mm2.559 in | N/A 65 mm2.559 in | N/A 100 mm3.937 in | N/A 130 mm5.118 in | |||||

| Rod Diameter (D2) | N/A 20 mm0.787 in | N/A 25 mm0.984 in | N/A 25 mm0.984 in | N/A 50 mm1.969 in | N/A 60 mm2.362 in | |||||

| Body Diameter (D3) | N/A 82 mm3.228 in | N/A 100 mm3.937 in | N/A 100 mm3.937 in | N/A 147 mm5.787 in | N/A 182 mm7.165 in | |||||

| Minimum Diameter (D4) (Not Supplied) | N/A 45 mm1.772 in | N/A 55 mm2.165 in | N/A 55 mm2.165 in | N/A 95 mm3.740 in | N/A 120 mm4.724 in | |||||

| Minimum Base Cross Corners Diameter (D5) | N/A 120 mm4.724 in | N/A 141 mm5.551 in | N/A 141 mm5.551 in | N/A 203 mm7.992 in | N/A 246 mm9.685 in | |||||

| Minimum Optional Gauge Diameter (D6) | N/A 80 mm3.150 in | N/A 98 mm3.858 in | N/A 98 mm3.858 in | N/A 145 mm5.709 in | N/A 180 mm7.087 in | |||||

| Base Square 1 | N/A 90 mm3.543 in | N/A 105 mm4.134 in | N/A 105 mm4.134 in | N/A 150 mm5.906 in | N/A 185 mm7.283 in | |||||

| Bolt Hole Pattern Square 2 | N/A 72 mm2.835 in | N/A 84 mm3.307 in | N/A 84 mm3.307 in | N/A 125 mm4.921 in | N/A 150 mm5.906 in | |||||

| Dimension (M) (x4) | N/A M8 | N/A M10 | N/A M10 | N/A M12 | N/A M16 | |||||

| Dimension (G) (x4) British Standard Pipe Parallel Thread (BSPP) Size | N/A G-3/8 | |||||||||

| Piston Area (P) | N/A 22.35 cm²3.464 in² | N/A 33.18 cm²5.143 in² | N/A 33.18 cm²5.143 in² | N/A 78.54 cm²12.174 in² | N/A 132.73 cm²20.574 in² | |||||

| Standard Features | N/A | |||||||||

| Popular Options | N/A | |||||||||

| Mounting Suggestions |

N/A

|

|||||||||

| Options |

N/A

Oil Return Option The oil return option can be an alternative to nitrogen, as a method of returning or retracting the H-2 unit. This option requires a hose from the H-2 unit to an external nitrogen/oil accumulator. The typical operating pressure of the forced oil return option is 100 bar (1450 psi). This option may require careful engineering analysis in order to calculate what is best for a customer’s application. READY can assist in this evaluation. User Sequence Option This option requires careful application engineering to determine feasibility. Engineering fees may apply. User sequence can allow customers to control the timing of their HYDROCAM® Systems. The H-2 unit can be programmed to extend, dwell, and retract at nearly any point in the stroke. This allows for multiple actions to be performed in a single operation. Contact Ready for the latest developments on this exciting HYDROCAM® system technology. Direct Punch Option This option is used when piercing round holes only. A metric punch of the proper size range can be used. The punch shank size is limited, and is listed on the bottom of the H-2 selection chart. By removing the standard front plate, the H-2 piston will accept a customer supplied head type punch. A special locking nut is included with this option. The direct punch option fits compact areas. |

|||||||||

| Piston Rod Travel | N/A Piston rod travel controls oil volume going to the H-2 unit(s). | |||||||||

| Optional Stroke Gauge Ring | N/A Used as a visual gauge to assist in set-up. Ring is located on top of pump body and made to the appropriate height based upon piston rod travel calculation. This stroke gauge ring is not a stop block and should be used for set-up purposes only. | |||||||||

| Total Stroke (Ht3) | N/A 31 mm1.220 in | N/A 32 mm1.260 in | N/A 47 mm1.850 in | N/A 34 mm1.339 in | N/A 38 mm1.496 in | |||||

| Product Code | N/A HC | |||||||||

|

|

||||||||||