Manufacturer Part# / Cross Reference Search

Please use this search function to find READY die set components that are equivalent to commonly used pins, bushing, ISO Springs, and Gas Springs from other manufacturers.  Please Note: We believe this cross reference to be accurate. Please review the specifications to ensure the item will work in your application. Gas Spring equivalents were based on body dimensions, on contact force and stroke length.

Please Note: We believe this cross reference to be accurate. Please review the specifications to ensure the item will work in your application. Gas Spring equivalents were based on body dimensions, on contact force and stroke length.

- "Next Day Die Set" - stock rectangular. "Order today, we'll ship tomorrow."

- Special Die Sets, both plain and ball bearing, and 3 Plate Die Sets.

- Aluminum Die Sets

- Blanchard Ground Plates, Special Machining, and Parallels.

Unit of Measure

Note

Note |

N/A It is recommended to finish heavy (point pressures) machining before grinding for best results. We do not recommend using steel and aluminum plates in a die set combination. |

Dimensions

Diagram |

N/A

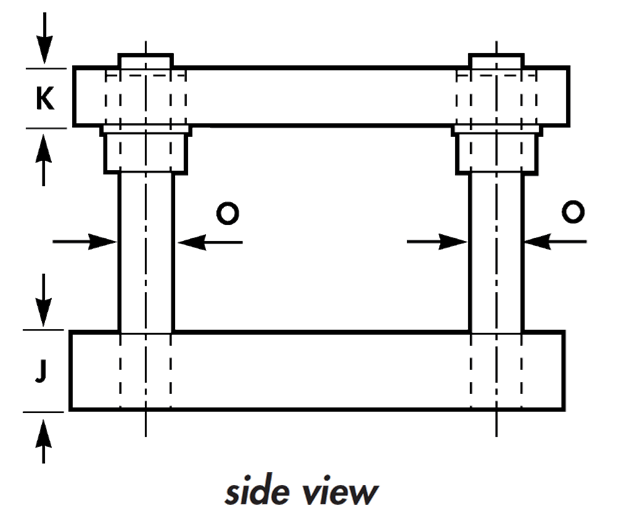

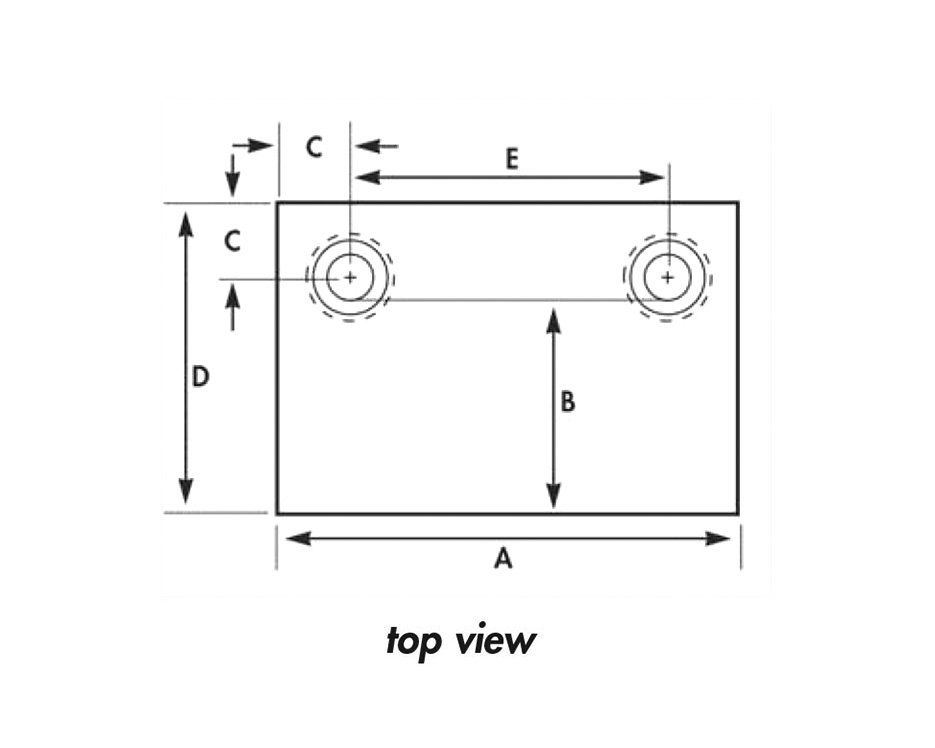

Standard Die Sets (Side View Diagram)  Standard, Two Post Plain Bearing Die Sets |

Dimension (A) (Left to Right) |

N/A 14 in |

Dimension (B) (Front to Back) |

N/A 10 in |

Dimension (C) |

N/A 1-3/4 in |

Dimension (D) |

N/A 12-1/2 in |

Dimension (E) |

N/A 10-1/2 in |

Die Holder Thickness (J) |

N/A 1-1/2 in |

Punch Holder Thickness (K) |

N/A 2 in |

Dimension (O) |

N/A 1-1/2 in |

Additional Information

Additional Information |

N/A

|

Advantages

Advantages |

N/A

|